|

Clearwater has created this webpage to provide background on

environmental dredging, which is distinctly different from dredging used

for navigational and construction purposes.

Navigation and Construction Dredging

This technology is used to remove accumulated sediment and debris from

waterway channels in order to improve navigation and also used for

construction projects. Large open clamshell dredges fall into this

category. These dredges are NOT used for cleaning up toxic materials

like PCBs, as GE has portrayed in its intentionally misleading,

multi-million dollar advertising ``blitz´´.

Environmental Dredging

Environmental dredging is used to remove contamination from targeted

areas. This technology is very precise and is designed to minimize

resuspension of small sediment particles that may be contaminated with

PCBs, heavy metals, or other toxic materials. This process is much more

controlled than navigational dredging, using technologies like the

hydraulic dredge, which functions like a large vacuum cleaner to remove

contaminated sediments with strong suction pumps.

Examples of hydraulic dredges include the cutterhead and the eddy pump.

Most hydraulic dredges have a cutting head to dislodge the contaminated

sediment which is immediately suctioned into a pipe. This diluted

sediment, or `slurry´, is pumped through a flexible, floating pipe to a

covered floating barge, or directly to an on-land dewatering facility,

where the sediment is allowed to settle out of the water. PCBs will

then be separated from the water by a multi-stage sand and carbon filter

system. The purified water is released back into the river cleaner than

the river water itself.

The sediment that accumulates at the bottom of the settling basin is

removed, dried, immobilized with cement-kiln dust, and shipped by rail

to a landfill near Buffalo, NY, that has been built to specifications

outlined in the Toxic Substances Control Act. Some of the `hotter´

sediments may be treated to remove and destroy PCBs before shipment.

These processes must occur in an enclosed environment to prevent

volatilization of PCBs.

Environmental dredging is much more precise than navigational dredging.

Environmental dredges are often fitted with GPS, video and/or sonar

equipment to monitor the process. During hydraulic dredging the river

remains clear enough to allow underwater cameras to guide the

operations. Multiple water testing sites are set up in the vicinity of

dredging so that if a problem should arise, it will be immediately

detected and the operation can be quickly shut down. Safety precautions

include silt curtains, which are used to surround the work area to

contain any loose sediment.

There is nothing new, untried, or experimental about environmental

dredging. Environmental dredges are proven effective. EPA has used

environmental dredging at many sites around the country, and state

environmental agencies also make wide use of these technologies. One

recent success story occurred in Cumberland Bay, part of Lake Champlain

near Plattsburgh, NY. In a cleanup ordered by the NYS DEC, one small

dredge boat removed sediment containing 25,000 pounds of PCBs over the

course of three summers. Two nearby swimming beaches remained open and

a paper mill process-water intake limited to 2 ppb sediment content

remained open despite being within 50 feet of the dredging operation.

Property values in Plattsburgh are reported to be rising. Waterfront

property owners observed ducks resting on the dredge vessel.

We expect the Hudson River to be another success story. There is no

data to support GE´s contention that the river will be closed to

swimming or navigation.

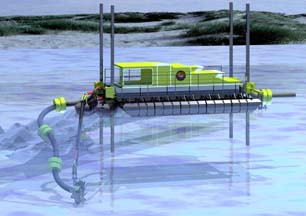

These photographs and graphics are examples of environmental dredges

which will be used in the clean up of the Upper Hudson River hotspots.

The examples shown are hydraulic cutterhead dredges. Once the

PCB-containing sediments have been removed by environmental dredging,

navigational dredges may be used to further open channels to boat

traffic. Snags, rocks, and sunken logs may have to be removed by

clamshell.

Thanks to Jim Gordon for his photograph of the dredge used in the Lake

Champlain clean-up. More details about the Plattsburgh cleanup are

available in Jim´s article,

`Dredging Works´.

Thanks also to Keene

Engineering, a manufacturer of dredging equipment, for allowing use of

photos and graphics from

their website.

Additional diagrams and photographs and a current report on dredging technologies entitled,

`Results of Contaminated Sediment Cleanups Relevant to the Hudson River´,

technologies are available on the

Scenic Hudson website.

Descriptions of environmental dredging are

available on

EPA´s website.

|

|

This little dredge boat removed tons of sediment containing 25,000

pounds of PCBs - about one quarter the amount to be removed from the

Hudson - over three summers. The Hudson River cleanup may require

several boats like this, and a small number of attendant barges - hardly

the vast destructive armada envisioned by GE.

-- Photo by Jim Gordon |

|

Environmental dredge graphics courtesy of Keene Engineering

Environmental dredge graphics courtesy of Keene Engineering